Among aficionados, there’s a commonly held belief that a cigar made by hand is inherently superior to one that has been made by a machine process.

In a world full of products that are becoming increasingly made by machines, it is indeed true that there is a growing romanticism attached to things that are still forged by handcraft. This however, certainly doesn’t mean that a machine-made cigar cannot be a wonderful thing too.

In this piece, we’ll take a peek into what goes into making cigars in both fashions. We’ll also query Colm O’Shea, VP of House Of Horvath in Toronto Canada about how his company has successfully been making great cigars for decades with the assistance of machines.

Hand Made Cigars

There’s a high probability that if you’re reading this, you’re likely a big proponent of enjoying cigars that are made by hand.

Cigars have been made by hand since the mid-16th century. Hand made cigars cost more – and for good reason, as they are typically made with long filler and are constructed of the finest tobacco leaf available by some of the most skilled artisans in the trade. Cigar boxes with cigars that are hand made may proudly proclaim “Totalmente Hecho a Mano“, meaning, “totally made by hand”.

When it comes to comparing hand made cigars vs machine made cigars, one major difference lies in the role of the roller.

The roller (or torcedor as they’re known in Spanish) very skillfully rolls a bunch of leaves entirely by hand in an attempt to maintain consistency in accordance with the cigarmaker’s blend. A roller must be incredibly meticulous and exact about measuring and cutting each cigar before it moves on to the next station. Years and years of practice are required to effectively hand roll cigars with consistency.

A Torcedor expertly rolls tobacco into what will become a beautiful cigar

Of course, one potential pitfall to hand rolled cigars can be human error and inconsistency. Machines have the ability to utilize a mechanized micro-precision that results in a better distribution of filler tobacco and an almost an exact aesthetic duplication from cigar to cigar.

This precision, despite years of practice, cannot be replicated in a human – it’s simply not possible.

As a result, sometimes hand made cigars can wind up with filler tobacco that is plugged and may draw poorly.

Today this is evidenced most commonly in Cuban made cigars.

However, another strong component of a hand made cigar is that it is also typically constructed of premium, 100% original tobacco leaf that hasn’t been reconstituted as HTL (Homogenized Tobacco Leaf). HTL is essentially a mixture of chopped scrap tobacco that is moistened and reconstituted as a sheet that can be cut in any shape to be used as the wrapper or binder of a cigar. It’s usually employed as a cost-saving mechanism but also for aesthetics, as it doesn’t feature veins and the toothy bumps that can be found in an original unaltered leaf.

Many hand made cigars are typically made of the finest long filler tobaccos

In short, cigars made in this fashion care generally constructed of the most top quality tobacco entirely by hand, and that is the universal appeal of a hand made cigar.

“The torcedor very skillfully rolls a bunch of leaves entirely by hand in an attempt to maintain consistency in accordance with the cigarmaker’s blend.”

HAND MADE CIGAR PROFILE: My Father le Bijou Grand Robusto 1922

Le Bijou is a rich, full-bodied treat in typical My Father form. Featuring a Habano Oscuro wrapper and a healthy mix of Nicaraguan long-fillers, Le Bijou 1922 exudes a robust array of flavors delivered in a remarkably smooth fashion. Complex, unique and satisfying.

Machine Made Cigars

Ok, if you’re still reading, then you’re likely curious to hear what we have to say about machine made cigars.

When you think of a machine made cigar, people tend to think that you simply pop some tobacco into a machine, press a few buttons and voilà! – out pops a finished cigar.

In actuality, it’s nothing like that at all.

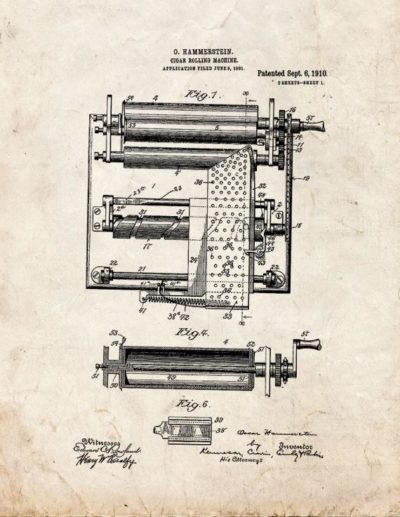

The first cigar rolling machines date back to 1885 and were created by a German businessman named Oscar Hammerstein.

By the 1920’s, Hammerstein’s fully-automated cigar making machines were being widely used as a way to produce mass market cigars in great quantities, and were even being commonly used in Cuba.

Original patent for Hammerstein’s Cigar Machine

In The US, Swisher was the first company to order rolling machines at their headquarters in Jacksonville, FLA in 1923. By the end of the 1920’s, Swisher was making 100 million cigars a year. At this time, cigar making machines were making more cigars in an hour than a hand roller could do in a day.

By the 1950’s Canadian companies such as H. Simon & Sons and The Ontario Tobacco Company Ltd. (now House Of Horvath Inc.) were using cigar making machines to roll tobacco of Cuban origin for the local population. These cigars were popular throughout North America and were typically referred to as ‘Clear Havanas’.

“This precision, despite years of practice, cannot be replicated in a human – it’s simply not possible.”

Today, many companies produce machine made cigars by utilizing special rolling machines to combine the cigar wrapper and the master blend to create a gorgeous, consistent, finished product. Cigars made by machine have a consistency in filler amount and distribution which assists in draw performance and encourages a more even burn.

They are also more affordable than hand made cigars as well, as they are typically made with short filler tobacco. Cigarillos and other small sized cigars cannot be made by hand like a regular premium cigar. They require the use of machines to help ensure the quality of the finished product. Smaller sized cigars such as Neos by J. Cortès or Principes by La Aurora are great for a short smoke when in a pinch.

Making cigarillos requires the assistance of a machine

Instead of referring to their cigars as machine made, companies like House Of Horvath prefer to classify their process as “hand assisted”.

House of Horvath’s Colm O’Shea expands on this process:

“Once the blends are prepared, the wrapper is handed to our tobacco stripper. The wrapper leaf of course has both a right and left side and is held together by a middle vein. The stripper is responsible for removing the middle vein, leaving just a right and left side.

Leaf Stripper Lourdes Gomes separates wrapper leaf in the factory at House Of Horvath

It is absolutely magical to see the tobaccos meet the machine and the cigar maker. The filler is held in a gravity feed hopper. Simple vibration shakes down the appropriate amount of filler and is then wrapped with a binder. The binder cigar is then rotated and a smaller amount of tobacco is added to the foot of the cigar to close the foot. On the back end of the machines is the roller, who prepares the left or right side wrapper for its bunch.

Wrapper leaf gets cut by a roller at House Of Horvath

It’s a form of ballet dances to the sounds of our pre-Castro cigar machines. Our team is both craftspeople and artisans, and their efforts produce our wonderful cigars”.

Despite some drawbacks in terms of tobacco quality, cigars made by machine assistance can make for a great, affordable everyday cigar. In addition to this, companies like House Of Horvath continue to set their sites on creating a ‘super-premium’ cigar that has been made through a machine assisted process.

MACHINE MADE CIAGR PROFILE: Bandi Corona Claro

Bandi Cigars are a smooth short filler cigar that have been proudly made by House of Horvath for more than 40 years and are a staple of the cigar business in Canada. With a natural leaf wrapper and a very affordable sticker price, Bandi are appropriate for any cigar lover – from novice to aficionado.

Summary: Machine vs Hand Made

There’s no denying that the world’s most sought after cigars are indeed hand made ones.

Despite this, the benefits of a cigar made by the assistance of a machine should not be overlooked, as taste comes from the materials used, not the mode of assembly.

Machine made cigars are more affordable, which certainly allows them to be enjoyed more frequently. They are more consistent in appearance and filler distribution, which typically results in a more even burn and draw from start to finish.

For many cigar lovers, machine made are a ‘hidden gem’ to be found within the sea of cigars that are available today.

Regardless of whether your next cigar was made by machine assistance or entirely by hand, you’re likely to have a wonderful experience with the many pleasures that smoking a cigar can bring.